Inletting a Tapered Pistol Barrel:

A friend had bought a Dixie .32 caliber tapered pistol about 40 years ago from Dixie Gunworks and wanted me to inlet it into a piece of walnut so he could have a pistol. I said sure. The following steps were taken to show you how I inletted this stock by hand. Hope you find it useful.

I measured the width of the barrel ahead of the breech and at the end. I drew a

center line down the stock and then I divided these measurement across the

center line. I extended the lines to the breech, because this barrel had a

side drum patent breech already installed on the barrel with built in

tang.

I measured the width of the barrel ahead of the breech and at the end. I drew a

center line down the stock and then I divided these measurement across the

center line. I extended the lines to the breech, because this barrel had a

side drum patent breech already installed on the barrel with built in

tang.

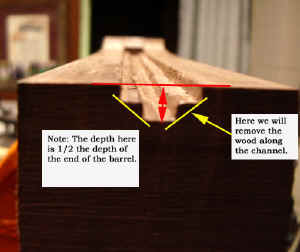

Now I used my knife and cut along the inside of these lines and "V" cut the lines. Using a 1/4" wood chisel, I removed started removing wood inside the lines.

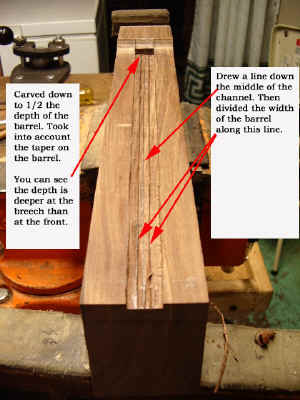

Important to note, this was a tapered barrel, however the side flats were slightly wider at the breech than at the end of the barrel. (See the photo to the left) Once I had the depth 1/2 the side flat of the barrel. I drew another center line down the channel. This will be the center flat of the barrel.

Using my knife, I again cut along the inside of these lines and "V" cut the lines. Using a 1/4" wood chisel, I removed started removing wood inside the lines. Now I only wanted to go 1/2 the depth of the barrel at the breech and at the end of the barrel. Taking measurements as I removed wood. This left me a nice "T" shaped channel.

The

next step is to remove the wood on either side of the channel. This will give me

the octagon barrel flat for the barrel.

The

next step is to remove the wood on either side of the channel. This will give me

the octagon barrel flat for the barrel.

Using my 1/4" chisel, I slowly removed the wood along each side, till the taper mated with the corners of the side and bottom flats.

Here is the channel established. Still have some cleaning up of the channel, because the barrel needs to be fitted into the channel.

The barrel was laid into the stock and the breech area for the drum was traced onto the wood and the wood was removed. Then the tang area was traced onto the stock and the wood was removed to depth. Using candle black, the stock was laid into the stock repeatedly until there was an even black coating along the barrel channel and in the tang area. Each time the barrel was removed, I used a 5/16" chisel knife to remove the black and occasionally scraped the barrel channel to even out any bumps.

Here are the finished photos of the barrel fully inletted the stock was cut out more.

Hoot AL Rifle Shop